|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

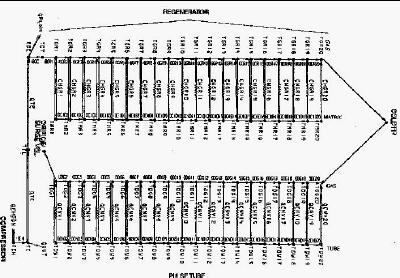

Please Visit Our Sponsor  Gift Shop Numerical Modeling of Cryocoolers (Cryogenics Refrigerators, Coolers, Engines)The modeling techniques range in degree of difficulty from the back-of-the-envelop calculation, to sophisticated nodal network analyses. We will start from the most simple approach. Zeroth Order Analysis This is probably the most simple analysis for modeling coolers. It was found empirically that the cooling capacity of a cooler Qe is proportional to the swept volume the compressor (Vc, in cm3), the mean charge pressure (Pm, in atm), the coldtip temperature (Te, in K), and the frequency (f, in Hz). The following equation has been found to give a ball-park number on the cooling capacity of a Stirling cooler. Qe = (f/2) TePmVc x 10-5 (Watts) First Order Analysis The first order analysis assumes ideal conditions as follows: During Isothermal compression, an amount of heat equals to Qc is being rejected from the compressor, which also equals to the work input (Wc). Qc = mRTc ln (Vmax/Vmin) = Wc During Isothermal expansion, an amount of heat equals to Qe is being absorbed into the expander. Qe = mRTe In (Vmax/Vmin) = We The coefficient of performance COP = Qe / W = Qe / (Wc - We) = Te / (Tc - Te) Second Order Analysis The second order approach is basically applying the ideal Schmidt analysis (First Order Analysis) with coupled loss terms. Some of the loss terms include, conduction loss Qcond, pressure drop loss Qpress, pumping loss Qpump, radiation loss Qrad, regenerator loss Qreg, and shuttle loss Qshut. Qcond = KA (Tc-Te) / L Qpress = 2 [((Pmax/Pmin)+1)/((Pmax/Pmin)-1)](DP/Pm) Qe Qpump = 2(pd)0.6 L(Pmax-Pmin)fCp)1.6(Tc-Te)t2.6 / (1.5Zkg0.6(R(Tc+Te)/2)1.6 Qrad = e s A (Tc4-Te4) Qreg = (1-eff) ma Cp (Tc-Te) / 2 Qshut = 0.186 s2 pd kg(Tc-Te) / t L The net refrigeration Qnet is the gross refrigeration Qe calculated from the Schmidt analysis minus all the above losses. Qnet = Qe - SQlosses In the above equations T stands for temperature, P - pressure, V - volume, subscripts c and e stand for compression and expansion, K and kg are the thermal conductivities of the coldfinger and the working gas. Coldfinger length, cross-sectional area and diameter are represented by L, A and d respectively. Regenerator efficiency, displacer stroke, and gap between displacer and coldfinger are represented by eff, t and s. Z and R are compressibility and gas constant. Third Order Analysis The third order analysis divide the cooler into different nodes. The equations of the conservation of energy (both gas and wall), conservation of mass and momentum are solved at each node until the solution converges. The author has great success in modeling various Stirling coolers in the literature using a third order approach. Excellent correlation was found between experimental data and analysis. Figure 1 is a schematic diagram of a dual-compressor Stirling cooler. In Figure 2, the Cooler is divided into a nodal network, with the majority of the nodes inside the regenerator where the temperature gradient is the steepest.

Figures 3 and 4 are the predicted PV power of the compressor and the expander respectively. Due to a redistribution of fluid mass in the cooler, the PV loops travel quite a few cycles before they converge. The PV power of the compressor (integration of the PV loop) plus the I2R and hysteresis losses gives the total motor power of the compressor. The Expander PV power (integration of the PV loop) minus expander losses as mentioned above gives the net cooling of the cooler.

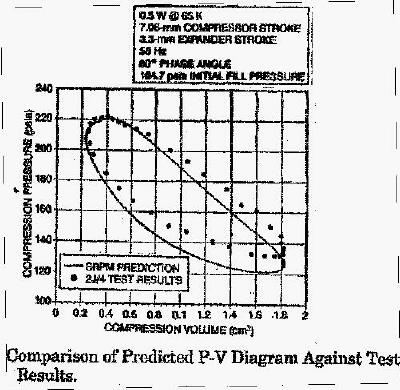

Figure 5 is a correlation between the predicted PV loop and that of the experimental data. The slight shift in the data could have been caused by the presence of extra volume introduced by the pressure sensor.  Figure 5 Figures 6 and 7 are correlations between the third order analysis and the experimental data of a Lucas Stirling Cooler on cooling capacity and specific power respectively.

In Figure 8, the third order analysis is compared to the data of a Philips Stirling Cooler. The optimum frequency predicted by the model compares favorably with the experimentally determined optimum frequency of the cooler. In Figure 9, the impact of dead volume on the optimum frequency of operation is shown.

Figure 10 is a nodal network diagram of a Pulse Tube. The same modeling approach for Stirling can also be applied to Pulse Tubes.  Figure 10 To show the accuracy of this third order model, a blind test was conducted with the help of Dr. Ray Radebaugh of NIST. The model was used to predict the performance of a pulse tube built by Dr. Radebaugh, who had not yet published the test data of this pulse tube. Figures 11 and 12 compares the prediction with the experimental data of cooling capacity and specific power of the pulse tube. As one can see, the third order approach is a very powerful tool in the analysis of cryocoolers, if done correctly.

"Experimental and Predicted Performance of the BEI Mini-Linear Cooler", Proc. of the 9th International Cryocooler Conference, Waterville, New Hampshire, P119, 1996 (with D.T.Kuo and A.S.Loc). "Prediction of Natural Frequency of the NASA 80K Cooler by the Stirling Refrigerator Performance Model", Cryogenics, 1994, vol. 34, No. 5, p.383 (with L.G. Naes and T.C. Nast). "Validation of the Stirling Refrigerator Performance Model Against the Oxford Refrigerator", Advances in Cryogenic Engineering, 1994, vol. 39, p.1359 (with I.E. Spradley and W.G. Foster). "Validation of the Stirling Refrigerator Performance Model Against the Philips/NASA Magnetic Bearing Refrigerator", Proc. of the 7th International Crycooler Conference, 1993, vol. p.280 (with I.E. Spradley). "Computer Simulation Model for Lucas Stirling Refrigerators", Cryogenics, 1992, vol. 32, No. 2, p. 143. (With I.E. Spradley, P.M. Yang and T.C. Nast.) "A Third Order Computer Model for Stirling Refrigerators", Proc. Advances in Cryogenic Engineering, 1992, vol. 37B, p. 1055. (With I.E. Spradley.) Abstract Download The same technique was applied to Pulse Tube coolers with great success also. "A Blind Test on the Pulse Tube Refrigerator Model", in Proc. of Advances in the Cryogenic Engineering, 1996, Vol. 41, p.1383-1388.(with Ray Radebaugh). Abstract Download "Validation of the Pulse Tube Refrigerator Model Against a Lockheed Built Pulse Tube Refrigerator", Cryogenics, 1996, Vol. 36, No.10, p.871. Abstract Download Do You Know Someone Who Needs A Job in Engineering, Physics or Chemistry? About the author- Dr. Sidney Yuan is a consultant in the field of Low Temperature Physics and Cryogenics, and has written a Book on Cryogenics and published extensively in the field. E-Mail. Bookmark This Page Send This Page To A Friend

Place Your Ad Here For As Little As $1 Per Day About Us | Add URL | Advertise with Us | Auction | Awards | Contact Us | Discussion Forum | Links | Search This Site | Send This Page | Shop | Top Ten Sites Copyright 2000 Yutopian, All Rights Reserved |

||||||||||

|